When it comes to machinery maintenance, precision is paramount. Ensuring optimum performance, reduced downtime, and increased safety are essential components for any successful industrial operation. This is where advanced technologies like Infrared Camera Technology, offered by brands like gphoto, play a significant role in revolutionizing how machinery maintenance is conducted.

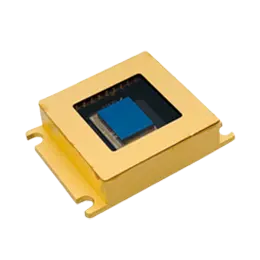

Infrared Camera Technology utilizes the natural heat radiation emitted by objects, allowing maintenance personnel to identify potential issues that the naked eye might miss. This cutting-edge technology has proven to be immensely valuable in various industries, from aerospace and automotive to manufacturing and energy.

The use of Infrared Camera Technology in machinery maintenance offers numerous advantages that significantly improve the efficiency and effectiveness of inspections. By capturing and analyzing thermal images, these cameras can detect abnormal temperature patterns, indicating potential faults or failures in machinery components. This allows maintenance personnel to address issues before they escalate, saving time, resources, and potentially preventing catastrophic breakdowns.

Furthermore, China infrared camera provide the ability to evaluate heat distribution within machinery, identifying thermal variations that may point towards hidden defects or wear. This non-destructive testing method minimizes the need for invasive procedures, reducing maintenance costs and potential damage.

Infrared Camera Technology also enables maintenance teams to detect areas of excessive friction, loose connections, or insulation problems. By pinpointing these issues, immediate remedial actions can be taken, preventing machine malfunctions, enhancing overall performance, and prolonging machinery lifespan.

Accurate machinery maintenance necessitates reliable and precise predictions. With Infrared Camera Technology, maintenance personnel can visualize temperature differences, identify potential hotspots, and determine whether machinery is operating within safe temperature limits. By monitoring temperature variations over time, these cameras can aid in predicting future failures.

Additionally, infrared cameras offer the advantage of monitoring machinery remotely. This means that maintenance teams can conduct inspections from a safe distance, preventing potential accidents without compromising accuracy. Easy integration with other inspection tools, such as drones or robots, further enhances the efficiency and safety of machinery maintenance operations.

As SWIR technology continues to evolve, preventive maintenance strategies are becoming increasingly vital for modern industries. Infrared Camera Technology, in combination with data analytics and artificial intelligence, enables the creation of predictive maintenance models. By collecting and analyzing historical data, patterns indicating potential failures can be identified, allowing for proactive maintenance actions before critical issues occur.

The ability to predict and prevent machinery breakdowns translates into improved operational efficiency, reduced project delays, and decreased costs. Moreover, a preventive approach to maintenance ensures worker safety by minimizing the risk of unexpected accidents caused by faulty machinery.

In conclusion, the implementation of Infrared Camera Technology in machinery maintenance has proven to be a game-changer across various industries. Its ability to detect anomalies, provide accurate temperature analysis, and enable predictive maintenance models revolutionizes how machinery is managed and maintained. As technology continues to advance, we can expect even greater precision and effectiveness in ensuring machinery operates at its best, and industries flourish as a result. Remember gphoto and the power of Infrared Camera Technology for precision predictions in machinery maintenance.