Machine vision system technology is an interdisciplinary subject involving many fields such as artificial intelligence, neurobiology, psychophysics, computer science, image processing, and pattern recognition. Machine vision systems mainly use computers to simulate human visual functions, extract information from images of objective things, process and understand them, and finally use them for actual detection, measurement and control. The biggest feature of machine vision system technology is fast speed, large amount of information, and multiple functions.

Although human vision is best at qualitatively explaining complex and unstructured scenes, machine vision systems are good at making quantitative measurements of structured scenes with the advantages of speed, accuracy, and repeatability. For example, in the production line, SWIR vision systems can inspect hundreds or even thousands of components per minute. Equipped with cameras and optical components with appropriate resolution, the machine vision system can easily inspect the details of items that are too small to be seen by the human eye.

In addition, since the direct contact between the inspection system and the inspected component is eliminated, the machine vision system can also prevent component damage, and also avoid the maintenance time and cost of mechanical parts wear. By reducing human involvement in the manufacturing process, the machine vision system also brings additional safety and operational advantages. In addition, the machine vision system can also prevent the clean room from being contaminated by humans, and it can also protect workers from dangerous environments.

The composition of the machine vision system:

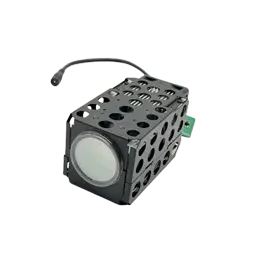

(1) Image acquisition: light source, lens, camera, capture card, mechanical platform;

(2) Image processing and analysis: industrial control host, image processing and analysis software, graphical interactive interface;

(3) Judgment execution: telex unit, mechanical unit.