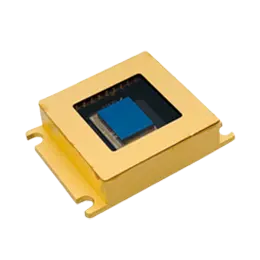

Short wave infrared (SWIR) sensors have become increasingly popular in industrial applications due to their unique capabilities and versatility. These sensors operate in the wavelength range of approximately 900 to 2500 nanometers, enabling them to penetrate through various materials and capture valuable information. In this article, we will delve into the wide range of applications of SWIR sensors in different industrial sectors, highlighting their transformative impact on manufacturing, quality control, and process optimization.

In this section, we will explore how SWIR sensors play a crucial role in quality control and inspection processes across industries. From detecting defects in manufacturing components to identifying contaminants in food processing, SWIR sensors provide real-time insights that help ensure product quality and safety. We will discuss specific examples and case studies where SWIR sensors have proven invaluable in optimizing quality control procedures.

SWIR sensors excel at detecting moisture content and liquid levels in industrial environments. This capability is particularly beneficial in industries such as pharmaceuticals, agriculture, and oil and gas, where precise measurement and control of moisture content and liquid levels are critical. We will delve into how SWIR sensors are employed for moisture detection, leak detection, and liquid level monitoring, enhancing efficiency and reducing waste.

SWIR sensors possess the ability to identify and classify different materials based on their unique spectral signatures. This capability finds extensive use in recycling facilities, mining operations, and material sorting processes. We will explore how SWIR sensors enable automated material identification, sorting, and recycling, contributing to resource conservation and sustainable practices.

SWIR sensors can also capture thermal information, making them valuable tools for thermal imaging and process monitoring in industrial settings. We will discuss how SWIR sensors complement traditional thermal cameras by providing enhanced accuracy, higher resolution, and the ability to penetrate certain materials. Applications such as equipment monitoring, energy audits, and thermal mapping will be explored in this section.

The non-destructive testing (NDT) industry benefits significantly from the capabilities of SWIR sensors. These sensors enable the detection of hidden defects, cracks, and structural irregularities without damaging the tested objects. We will examine how SWIR sensors are applied in NDT methods such as thermography, radiography, and fluorescence imaging, revolutionizing the inspection processes in industries such as aerospace, automotive, and construction.

The applications of SWIR sensors in the industrial sector are diverse and ever-expanding. Their ability to capture information beyond the visible spectrum, coupled with their compact size, durability, and real-time data acquisition, make them invaluable tools in optimizing manufacturing processes, improving quality control, and driving overall efficiency. By exploring the applications of SWIR sensors in industry, we can appreciate their transformative impact on various sectors and anticipate further advancements in the future.